Custom Dietary Supplement Contract Manufacturing

Build Your Nutrition Brand With Science, Speed & Compliance

AirVigor’s custom contract manufacturing program combines 20+ years of sports nutrition R&D, GMP-certified production, and global fulfillment power to help brands launch high-performance hydration, electrolyte, creatine, protein, and advanced functional formulas. Whether you’re a fitness creator launching your first supplement or a global retailer scaling a full product line, we provide formulation, testing, production, flavor engineering, labeling, and Amazon/FBA-ready packaging—fully managed under one scientific, compliant, and traceable system.

Your brand, powered by AirVigor science.

Why Brands Choose AirVigor Contract Manufacturing

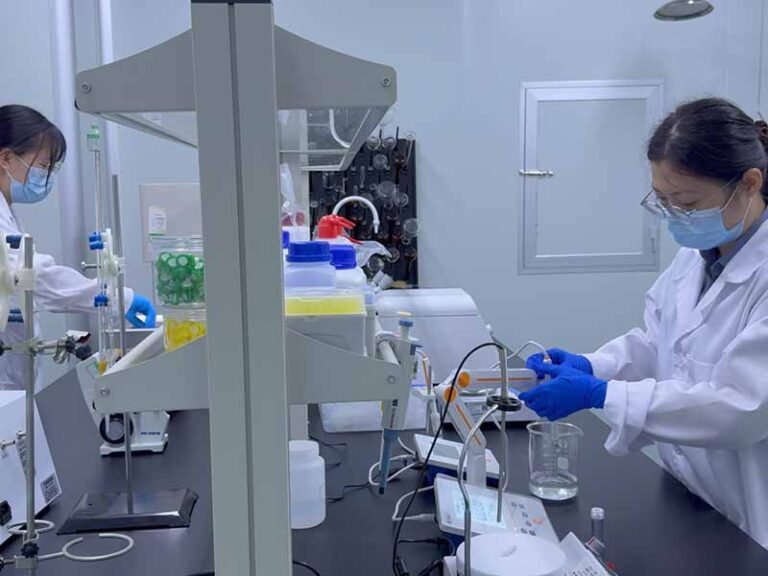

Science-Backed Manufacturing for Modern Dietary Supplement Brands

AirVigor is not a typical supplement manufacturer—our foundation is sports nutrition science, clinical-grade formulation, and global market experience across 120+ countries. With 20,000+ formula models, 300+ patents, and a full internal lab capable of purity testing, solubility testing, stability simulation, and sensory optimization, we support brands that require accuracy, transparency, and measurable performance.

We manage everything from R&D → formulation → sampling → compliance → packaging → production → FBA fulfillment. Our clients include fitness creators, e-commerce brands, sports teams, wellness retailers, and international distributors.

What We Can Manufacture for You

End-to-End Production Across All Performance Nutrition Categories

AirVigor manufactures a complete portfolio of functional and sports nutrition products, with strict testing for purity, dosage accuracy, and global compliance.

Product Capabilities Include:

- Electrolyte Powder (0-sugar, fast dissolving, endurance blends, recovery blends)

- Creatine Monohydrate / Creapure-style alternatives

- Protein Powders (whey, isolate, collagen, vegan blends)

- EAA / BCAA blends

- Hydration + Collagen formulas

- Advanced Recovery Powders (Mg+, Ca+, mineral complexes)

- Nootropic blends (energy, focus, cognitive support)

- Daily Wellness & Metabolic blends

- Functional gummies, capsules, tablets

- Stick packs, tubs, pouches, bulk packaging

All formulations can be customized based on athletic intensity, lifestyle, region-specific regulations, and brand positioning.

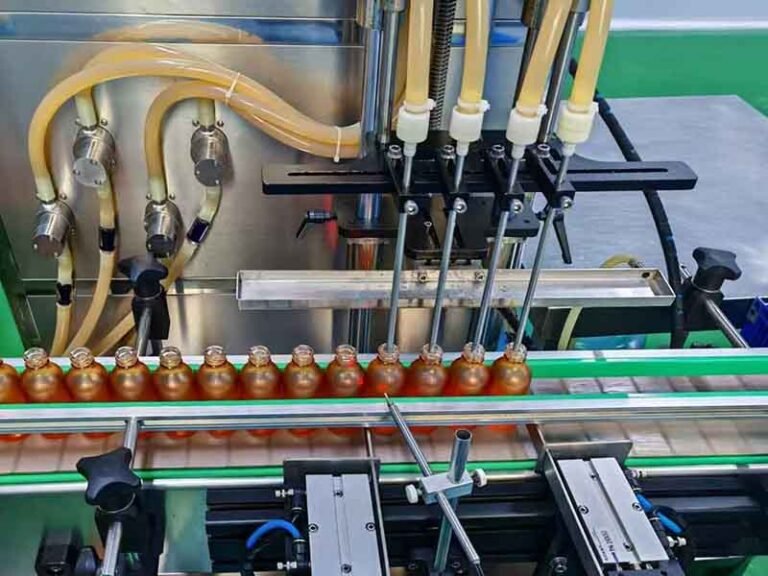

AirVigor’s GMP, HACCP & FDA Compliant Production Ecosystem

A Fully Traceable, Science-Controlled Manufacturing System

AirVigor operates a vertically integrated manufacturing chain:

- GMP, HACCP, ISO22000 certified supplement factory

- Food-grade packaging film plant

- Internal printing factory for compliant labels

- FDA, FSSC, Halal, Kosher, MSDS, COA support

- 10,000-level cleanroom & 15,000+ m² facility

Every product’s lifecycle is tracked internally—from raw material receiving → batching → testing → filling → sealing → labeling → lot tracking → export compliance. This ensures consistency, faster production, traceability, and reduced risks compared to outsourcing.

Custom Formulation & Flavor Engineering

Your Formula — Built by Scientists, Refined by Athletes

AirVigor offers one of the industry’s most advanced custom formulation programs, backed by 20+ years of real-world sports performance data.

What We Customize:

- Electrolyte Structures (precise sodium–potassium–magnesium ratios for different sports)

- Performance Additives (creatine, beta-alanine, taurine, betaine, B-vitamins)

- Endurance vs Recovery formulas

- Hydration-speed optimization (osmolarity control, dissolution rate engineering)

- Clean-label versions (no sugar, natural flavors, non-GMO)

- Clinical dosing standards

- Country-specific regulatory adjustments

Flavor Engineering

We design flavors that dissolve fast, stay stable across climates, and satisfy global palates. Options include:

- Tart citrus blends for endurance athletes

- Light hydration flavors for yoga/pilates users

- Fruity profiles for general fitness

- Zero-sweetness “water-like” hydration flavors for performance athletes

- Natural botanical notes for premium brands

Each flavor is stability-tested under heat, humidity, shaking, and long-term storage to mirror real usage conditions.

Ingredient Sourcing, Safety, and Compliance System

Globally Verified Ingredients for Clean, High-Performance Formulas

AirVigor’s contract manufacturing system is built on a zero-compromise ingredient standard, ensuring every formula—electrolytes, hydration mixes, creatine, protein, amino blends, metabolic support—is grounded in certified raw materials and transparent supply chains.

Our sourcing network spans USA, Germany, Japan, South Korea, New Zealand, India, and each supplier undergoes multi-step verification:

12-Step Supplier Verification Program

- GMP, HACCP, ISO22000 plant audits

- COA & purity verification for every batch

- Heavy metal, microbe, allergen testing

- Identity testing using FTIR/HPLC

- Stability evaluation under multiple humidity & temperature profiles

- Ingredient traceability mapping

- Shelf-life modeling by AirVigor Laboratory

Certified Ingredient Categories

- Pharmaceutical-grade electrolytes (Na, K, Mg, Ca)

- Fermented, monohydrate, and micronized creatine

- Hydrolyzed & whey isolate proteins

- BCAA/EAA using Ajinomoto-grade amino acids

- Natural sweeteners (stevia, monk fruit)

- Natural colors & flavors free from artificial additives

- Functional botanical actives (adaptogens, antioxidants)

Compliance Coverage (Global-Ready)

Every material can be pre-validated for:

- FDA (USA)

- NSF Sport

- EU Novel Food / EFSA

- Japan FOSHU

- Australia TGA

- Halal

- Kosher

- Non-GMO / Organic

Manufacturing Capabilities Across Powders, Capsules, Gummies & Liquids

Your Formula — Built by Scientists, Refined by Athletes

AirVigor operates a vertically managed manufacturing ecosystem designed for elite supplement brands that require speed, scale, and science-driven accuracy.

Powder Manufacturing

For electrolytes, creatine, protein, metabolic blends, recovery complexes:

- Ribbon & V-blender mixing

- Particle-size harmonization

- Flavor dispersion engineering

- Hygroscopic ingredient protection

- Micro-batch R&D → large-scale transition

- High-precision powder filling (±1% deviation)

Capsule Manufacturing

For pure functional actives or synergistic combinations:

- Gelatin / veggie capsules

- Size 0–3 options

- High-speed encapsulation 150,000+ pcs/hr

- Dissolution testing

- Weight uniformity control

Gummy Manufacturing

For lifestyle and wellness SKUs:

- Pectin or gelatin base

- Natural colors/flavors

- Active-ingredient retention tests

- Low-sugar systems

- Mold design customization

Liquid Manufacturing

For shots, tonics, mineral concentrates:

- Heat-stable & micro-filtered systems

- Flavor masking support

- Shelf-life modeling

- Custom bottle molds available

Full QA/QC Controls

- Batch fingerprinting

- Moisture & density measurement

- Microbiology

- Heavy metal compliance

- Dissolution rate testing

- Accelerated stability testing

End-to-End Packaging, Labeling & Brand Presentation

High-Performance Packaging Engineered for Athletes & Retail

Your packaging is not just a container—it’s a conversion tool. AirVigor designs supplement packaging with scientific clarity + on-shelf impact + regulatory precision.

We provide:

- Custom dielines for all formats (stick packs, pouches, tubs, bulk)

- Moisture-barrier & oxygen-resistant films for powder stability

- Heat-sealing optimization for high humidity environments

- Scratch-proof & sweat-proof labels for gym use

- Amazon FBA-ready packaging (barcode placement, carton specs, drop-test compliant)

- Retail-grade branding systems for gyms, nutrition shops & big-box stores

- Minimalist “science-first” design language aligned with AirVigor’s visual DNA

Every label goes through: three-stage review — R&D → Regulatory → Production QA to prevent mislabeling or recall risks.

Quality Control, Batch Testing & Traceability System

Precision Testing for Potency, Purity & Performance

AirVigor’s quality framework is engineered to remove inconsistency—the #1 reason supplement brands lose consumer trust.

Every batch undergoes:

- Identity testing for all active ingredients

- Purity analysis (heavy metals, microbial load, pesticides)

- Potency verification (electrolytes, amino acids, creatine monohydrate, collagen peptides, minerals)

- Solubility & stability testing under varied temperature/humidity

- Flavor consistency audits using trained sensory panels

- QR-based traceability from raw material → production → warehouse → consumer

Our 25-person QC team ensures your formula delivers the same experience, taste, and efficacy—batch after batch—globally.

Certifications, Compliance & Regulatory Support

Global-Ready Documentation, Label Review & Ingredient Verification

AirVigor’s contract manufacturing program includes full regulatory compliance support for the U.S., EU, UK, Canada, Australia, Japan, and emerging markets. Our in-house regulatory team ensures every formulation, label statement, dosage instruction, allergen declaration, and structure/function claim meets market-specific supplement regulations.

We maintain a full certification ecosystem to help your products launch globally without delays:

- FDA-registered facilities

- GMP, HACCP, ISO22000, FSSC certified manufacturing

- COA for every batch (purity, identity, potency)

- MSDS, Heavy Metal & Microbial Reports

- Halal, Kosher, Organic Certifications (upon request)

- EU-compliant ingredient lists & claim language

- Japan Foods for Specified Health Uses (FOSHU) adaptions

- Australia TGA labeling guidance

Our team conducts risk screening for banned substances, stimulant sensitivities, and athlete-approved ingredient lists—ensuring your products are market-safe, audit-proof, and trusted by consumers.

Fast Sampling, Transparent MOQs & Predictable Timelines

AirVigor makes the contract manufacturing process fast, predictable, and entrepreneur-friendly.

Sampling

- Standard formulations: 3–7 days

- Complex or new ingredient sourcing: 7–12 days

- Samples provided as: stick packs / jars / pouches

MOQ Options

- 500 units for test market launches

- 3,000–10,000 units for wholesale/retail scale

- Flexible for multi-SKU bundles

Production Timelines

- Standard orders: 15–30 days

- Large volume or multi-format: 30–45 days

What We Handle for You

- Formula refinement

- Label compliance

- Packaging engineering

- Production & QC

- Freight coordination

- Amazon FBA prep

- Multi-country warehouse distribution

From startup brands to global chains, we provide a structured, low-friction path to launch.

Case Studies

Proven Systems That Turn Concepts Into Scalable Global Brands

AirVigor’s contract manufacturing system is built on a zero-compromise ingredient standard, ensuring every formula—electrolytes, hydration mixes, creatine, protein, amino blends, metabolic support—is grounded in certified raw materials and transparent supply chains.

Our sourcing network spans USA, Germany, Japan, South Korea, New Zealand, India, and each supplier undergoes multi-step verification:

CASE STUDY 1 — Scaling a U.S. Performance Hydration Brand to 7-Figure Revenue

Category: Electrolyte & Recovery Powder

Challenge: A fitness coach-founded startup needed clinical-dose electrolyte formulas, clean labeling, and Amazon FBA readiness while competing with major hydration brands.

AirVigor Solution:

- Developed 3 formulations: endurance, daily hydration, and recovery

- Provided flavor engineering to reduce bitterness & metallic notes

- Designed full packaging system (stick packs + tubs)

- Executed FBA cartonization & pallet preparation

- Delivered inventory to 3 regional Amazon warehouses

Outcome:

- Achieved 4.7+ average rating in 6 months

- First year revenue: $1.2M

- 63% returning-customer ratio

- Entered 4 new marketplaces (US, CA, UK, DE)

CASE STUDY 2 — European Brand Launching a Premium Creatine System

Category: Monohydrate + Electrolyte Hybrid System

Challenge: A German endurance brand needed a scientifically validated creatine blend, EU-compliant labeling, and a rapid go-to-market timeline.

AirVigor Solution:

- Developed micronized creatine + hydration synergy formula

- Performed EFSA-aligned label validation

- Positioned 3 flavors with minimal sweetness

- Packaged in EU-approved recyclable tubs

- Deployed inventory to German + UK warehouses

Outcome:

- Sell-through rate doubled in 90 days

- Retail partnerships with 14 European shops

- Expanded SKU line from 1 to 8 products

- 32% increase in subscription customers

CASE STUDY 3 — APAC Wellness Brand Requiring Full ODM Development

Category: Daily Hydration + Beauty Electrolyte Mix

Challenge: A Japanese lifestyle wellness brand sought a beauty-hydration hybrid formula with collagen, vitamin C, and electrolytes.

AirVigor Solution:

- Built collagen-electrolyte fusion system with neutral flavor

- Designed premium sachets for the Japanese market

- Provided zero-sugar flavor optimization

- Delivered long-term stability testing

- Supported Rakuten and Shopee listing compliance

Outcome:

- 45,000 units sold in first 60 days

- Received 4.8+ rating across channels

- Became Amazon Japan’s “Rising Star” hydration category brand

- Opened B2B wholesale channels in Singapore & Taiwan

FAQ

1. What types of supplements can AirVigor manufacture?

We specialize in electrolytes, creatine, protein powders, amino acid blends, collagen hydration formulas, minerals, nootropic energy blends, recovery complexes, and multi-phase performance systems. We support powders, capsules, tablets, gummies, and functional beverages.

2. Can you develop a completely custom formula from scratch?

Yes. Our scientists can build formulas based on your desired benefits, athlete profile, clinical dosage targets, flavor preferences, and market positioning. We create several prototype variations so you can compare taste, solubility, and performance.

3. What certifications do your facilities hold?

FDA-registered, GMP, HACCP, ISO22000, FSSC, Halal, Kosher, Organic, plus full COA/MSDS documentation per batch. Suitable for global market entry.

4. Do you support Amazon FBA brands?

Absolutely. We provide FNSKU printing, carton packaging optimization, FBA labeling, barcode placement, carton drop-test compliance, and direct-to-FBA freight.

5. Can you match or reverse-engineer an existing product?

Yes. We can reverse-engineer popular market formulas or competitor products, then upgrade taste, solubility, or ingredient profile to help you differentiate.

6. What is your MOQ?

MOQ begins at 500 units for most powdered products—ideal for DTC testing, brand launches, or micro-retail deployment.

7. How long does production take?

Standard manufacturing requires 15–30 days after formula approval and packaging confirmation. Complex multi-SKU programs may take slightly longer.

8. Do you handle global shipping?

Yes. AirVigor provides shipping to the U.S., Canada, EU, UK, Australia, Japan, Korea, and LATAM through DHL, UPS, FedEx, USPS, and bonded warehouses.

9. Can I visit your factory?

Yes. Facility tours (on-site or virtual) are available with appointment. We demonstrate R&D labs, production lines, QC systems, and packaging operations.

10. How do I get started?

Simply share your product goals, target audience, intended benefits, format, and MOQ. Our team will prepare a proposal, formulation map, and sampling plan.

Let’s Build Your Supplement Line Together

Work With a Contract Manufacturer Trusted by Athletes Worldwide

Whether you’re scaling an existing nutrition line or launching a new electrolyte, creatine, protein, or functional blend, AirVigor gives you science-driven formulation, FDA-registered production, global fulfillment capabilities, and athlete-tested performance validation.

We combine 20+ years of R&D expertise, multi-market regulatory knowledge, and Amazon-proven packaging systems to give your brand the manufacturing partner it deserves.

From concept → formulation → compliance → production → FBA → global delivery: We handle everything. You scale confidently.